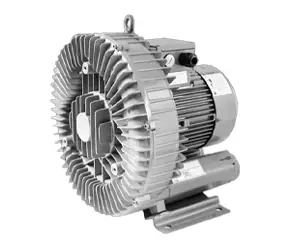

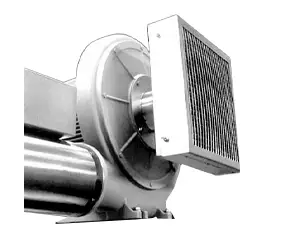

Air Knife Systems – Bespoke Drying Solutions – Centrifugal Fans – Side Channel Blowers – Process Air Heating

Airtec Air Systems are industry leading experts in the supply of air knife drying systems, industrial centrifugal fans, side channel blowers, exhausters and in-line electric process air heaters to both end users and OEMs in a variety of industrial markets. Using a combination of our products and many years of experience, we also offer bespoke systems that can be tailored to suit your exact requirements.

ABOUT AIRTEC

Based in Mossley, Lancashire, we have recently expanded to a brand new purpose built office/warehouse facility which holds the largest stock of side channel and centrifugal blowers currently in the U.K. This enables us to offer a fast turnaround for a wide range of our standard products on an ex-stock basis.

Meet The Airtec Air Systems Team

All components and systems are offered with a full performance warranty.

We also offer demonstration systems, on site evaluation and consultancy services for your complete peace of mind.

PARTNER WITH US FOR AN END TO END AIR KNIFE SOLUTION

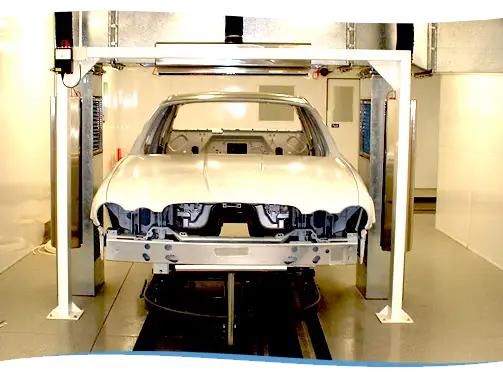

Air Drying System We Created For Aston Martin

We are proud of the working relationships we have with our clients. When you decide to choose Airtec as your air knives provider, you will find that we work closely with you every step of the way through the process until final installation.

Each client is different and each have unique requirements, so no two processes are the same, but here is a general idea of what to expect when we start working together:

- Initial consultation to assess your needs.

- Internal meetings at Airtec to discuss possible solutions.

- Proposal presentation to showcase solutions that we have decided best fit your situation.

- Agreement contract signed and stamped.

- Internal Airtec team creates and completes designs for your bespoke solution.

- Designs are passed to our manufacturing department to be made.

- Our installation team arrives at your site and fits your new solution (if required).

- Contract maintenance begins (if required).

Needless to say, we keep in close contact with you at every stage of the process and there may be extra meetings needed to go over some finer details.

SOME OF OUR EXISTING CLIENTS AND THEIR PROJECTS

Hydrus

Airtec air systems in conjunction with Hydrus Hygiene Limited were commissioned to improve a number of existing site facilities.

If you are looking for an air knife solution for your workplace, please do give us a call. We happy to chat about any project or problem that you may have that could benefit from one of our bespoke air knife builds and give you any advice you might need.

Our number is 01457 832 724 – we hope to be working with you soon.