ACCESSORIES BY AIRTEC AIR SYSTEMS

Airtec can supply a wide range of accessories to complete and installation. Common categories include, though not limited to;

Inline Vacuum Filters

Please Click Here to download our Inline Vacuum Filters information PDF

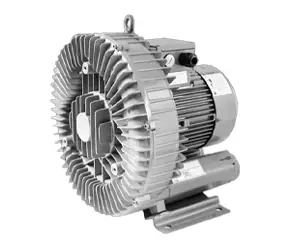

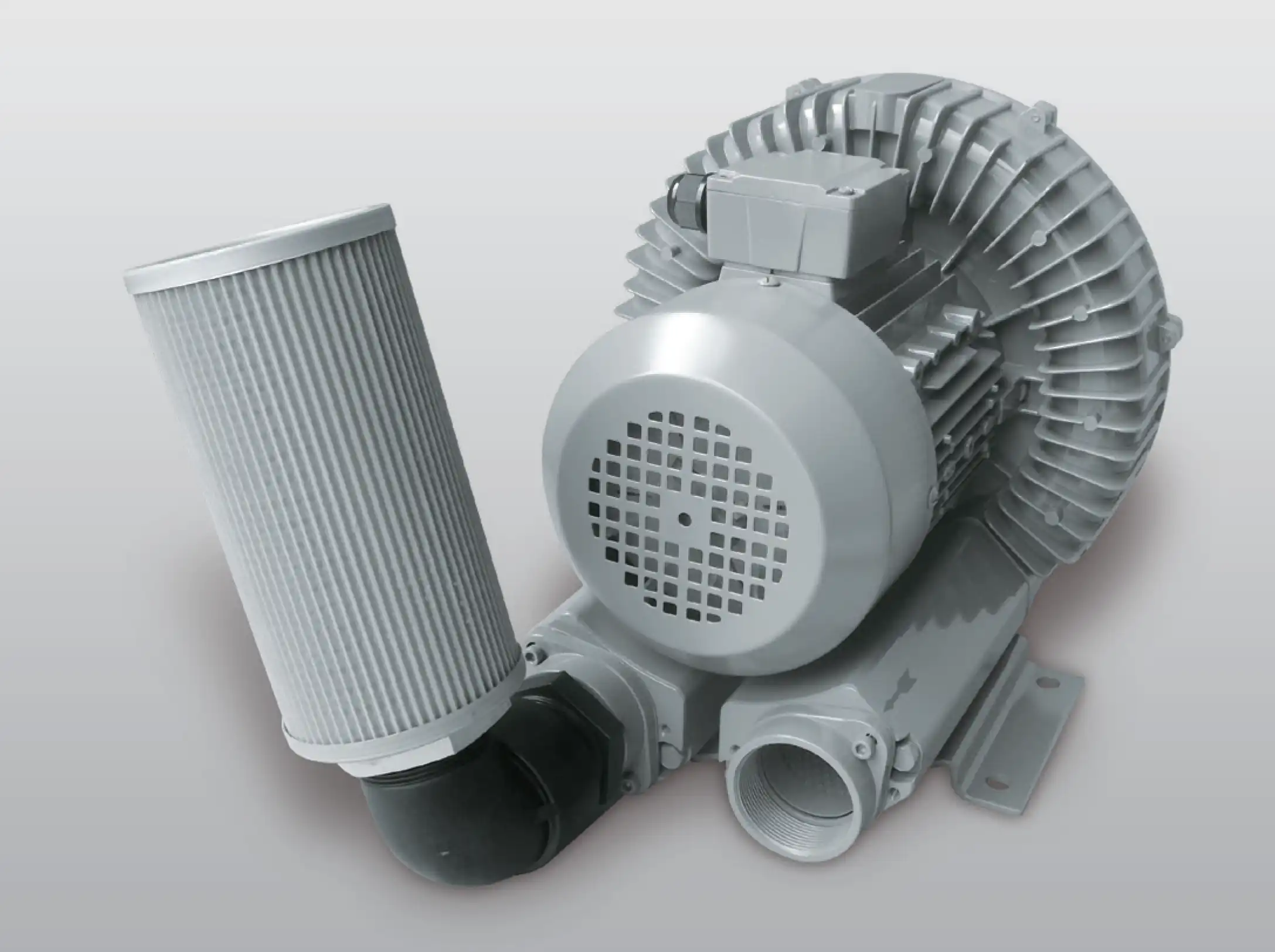

Filters (Blowing)

A range of filters is available to compliment our range of side channel blowers. The stock filters are the minimum recommended requirement to protect the blower, finer filtration levels up to HEPA specification are also available on request.

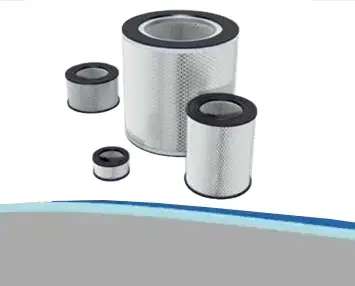

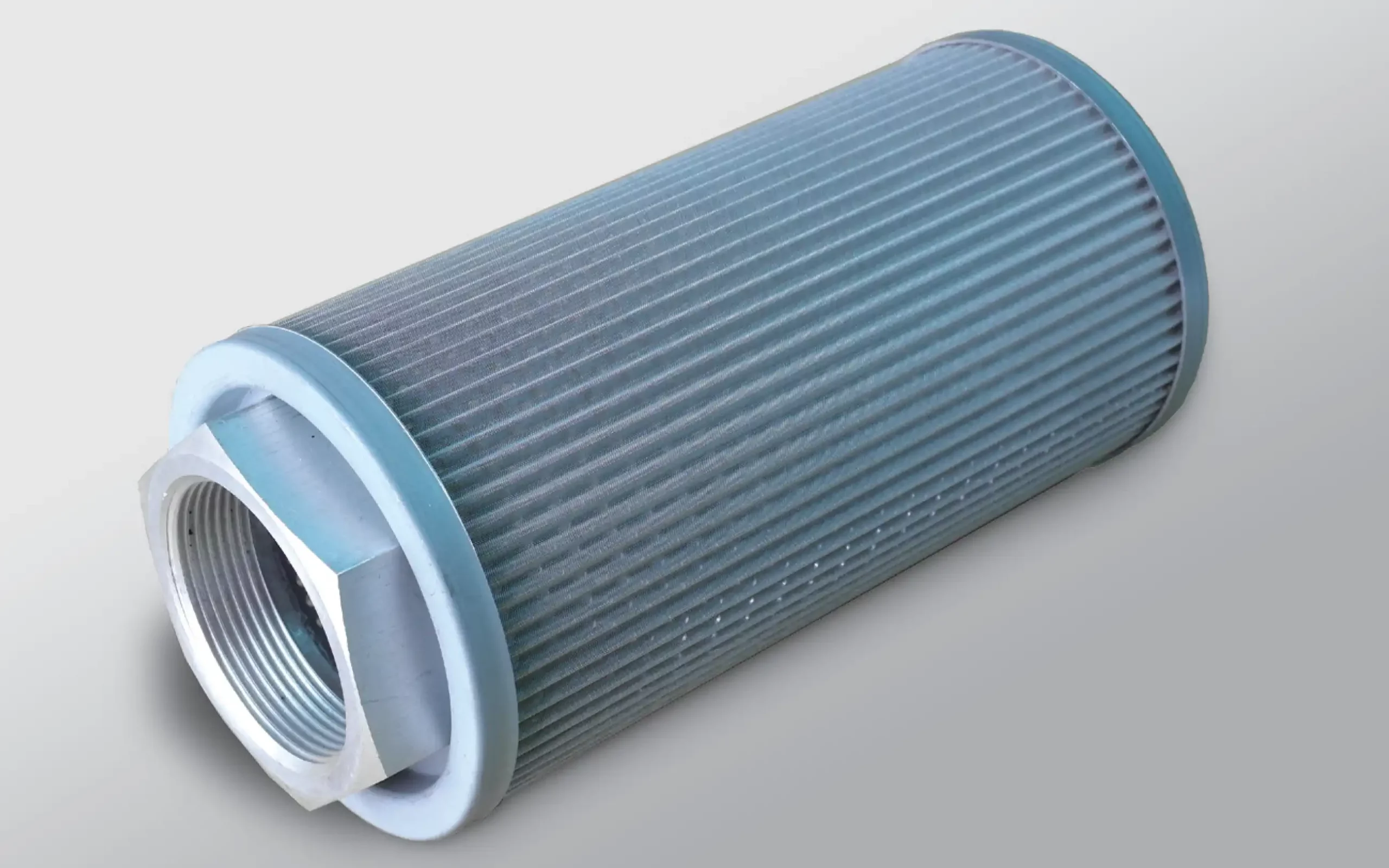

Filters (Vacuum)

Designed primarily for vacuum applications using side channel blowers. Filter level to 5 micron. Washable polyester elements also available.

Airtec can supply a wide range of accessories to complete and installation. Common categories include, though not limited to;

Flexible Hoses

Flexible Hoses

Airtec supply a large variety of hose types to suit the application in hand including high temperature and food grade hosing.

All hosing is manufactured in the UK. Please contact us with your specific requirements.

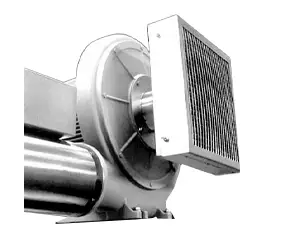

Acoustic Enclosures

Acoustic Enclosures

Certain applications require an acoustic enclosure to reduce the sound pressure level of a blower to meet or exceed specified levels as set out in H.S.E Guidelines.

Please contact us with your specific requirement by calling us on 01457 832 724 or by Clicking Here

Pressure Relief Valves

Pressure Relief Valves

Provides the user with a simple spring loaded valve to avoid an over load.

The Valves can be used for suction and extraction.

The Relief valves are easily adjusted to suit the required back pressure/vacuum with simple adjustment of a screw.

Fittings

Fittings

Airtec Stock a selection of high quality stainless and galvanised fittings and adapters.

Bespoke Adapters and fittings are available on request.

Please contact us with your specific requirement by calling us on 01457 832 724 or by Clicking Here

ACCESSORIES BROCHURE

You can download the .pdf Viewer software by Clicking Here

PRESSURE RELIEF VALVES

You can download the .pdf Viewer software by Clicking Here

FS-18P-151 DOCUMENTS

You can download the .pdf Viewer software by Clicking Here

18S ELEMENT DOCUMENTS

You can download the .pdf Viewer software by Clicking Here

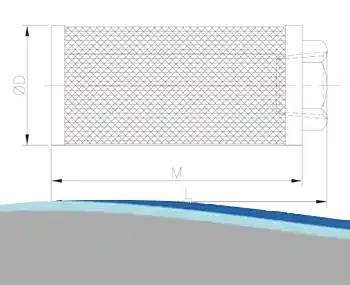

FILTER DRAWINGS

You can download the .pdf Viewer software by Clicking Here

INLET FILTERS

You can download the .pdf Viewer software by Clicking Here

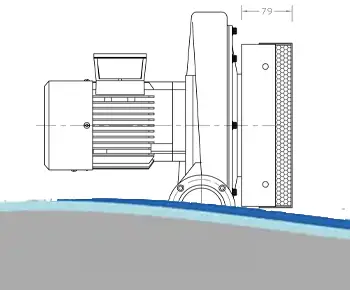

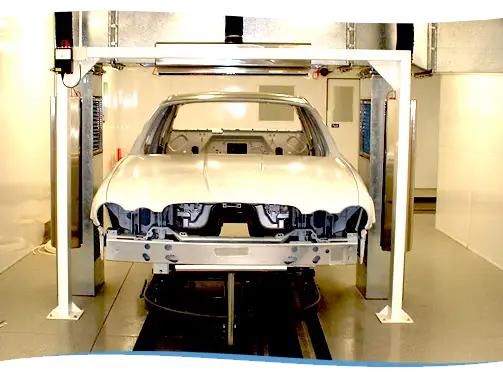

PARTNER WITH US FOR AN END TO END AIR KNIFE SOLUTION

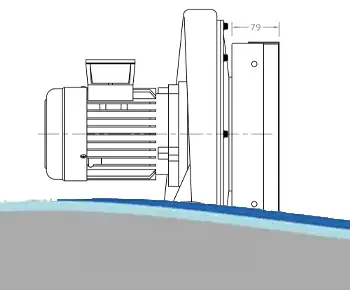

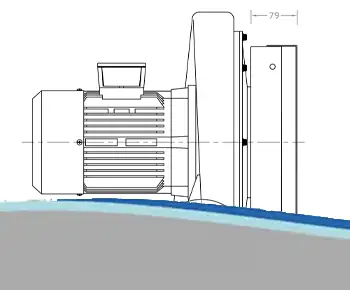

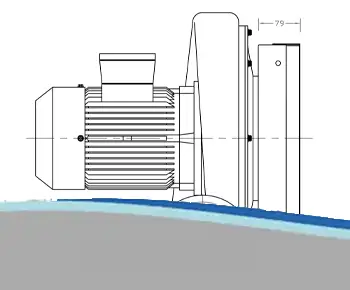

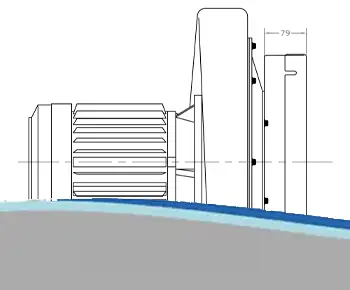

Air Drying System We Created For Aston Martin

We are proud of the working relationships we have with our clients. When you decide to choose Airtec as your air knives provider, you will find that we work closely with you every step of the way through the process until final installation.

Each client is different and each have unique requirements for their Air Knives, so no two processes are the same, but here is a general idea of what to expect when we start working together:

- Initial consultation to assess your needs.

- Internal meetings at Airtec to discuss possible solutions.

- Proposal presentation to showcase solutions that we have decided best fit your situation.

- Agreement contract signed and stamped.

- Internal Airtec team creates and completes designs for your bespoke solution.

- Designs are passed to our manufacturing department to be made.

- Our installation team arrives at your site and fits your new solution (if required).

- Contract maintenance begins (if required).

Needless to say, we keep in close contact with you at every stage of the process and there may be extra meetings needed to go over some finer details.

SOME OF OUR EXISTING CLIENTS AND THEIR PROJECTS

Hydrus

Airtec air systems in conjunction with Hydrus Hygiene Limited were commissioned to improve a number of existing site facilities.

If you are looking for an air knife solution for your workplace, please do give us a call. We happy to chat about any project or problem that you may have that could benefit from one of our bespoke air knife builds and give you any advice you might need.

Our number is 01457 832 724 – we hope to be working with you soon.