AIR KNIVES MANUFACTURED IN THE UK

- WELCOME TO AIRTEC

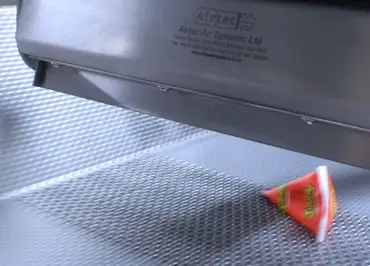

Air Knives deliver a non-contact method for product drying, coating, cleaning and cooling during production and are used in the manufacture of food, automotive and industrial parts; they remove surface moisture or excess debris from products as they traverse through the manufacturing process.

At Airtec, we are industry leading specialists in the design and manufacture of completely bespoke air knife systems which can be tailored exactly to your requirements. We can offer a complete service package from initial consultation and design right through to installation and commissioning.

AIR KNIVES : HOW THEY OPERATE

Air knives generate and direct low pressure/high volume air. Air knives produce a highly controlled, non-contact solution for removing surface moisture or debris from virtually any product during a manufacturing process.

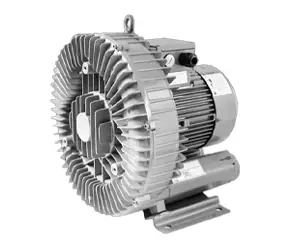

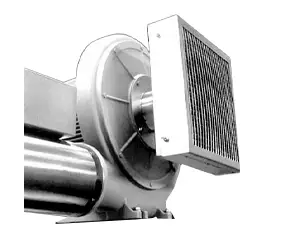

The air Knives are positioned at strategic positions along the manufacturing process to clean or dry the products as they traverse past. Air is forced through the air knife slots via an Airtec industrial blower, to deliver the exit air volume and velocity needed to efficiently remove moisture or debris from virtually any product or surface during manufacture. Airtec industrial blowers are high quality robust units that are precisely load matched to provide optimum performance and efficiency.

Our bespoke air knife drying systems have been successfully implemented into a bewildering variety of different industrial applications. From swarf removal of aircraft parts to drying lobsters as part of an in-line production process, Airtec have an enviable portfolio of successful systems in virtually every industry. Air knives have four main application areas: Drying, Cooling, Coating and Dust /debri removal. Here are some examples of how those are used in real world applications:

AIR KNIVES AND TYPICAL PRESSURE REQUIREMENTS FOR COMMON APPLICATIONS

| Application | Compressed Air | Blower Driven |

| Liquid removal and drying | From 60 to 80 PSIG | From 2 PSIG |

| Coating setting & drying | From 20 to 30 PSIG | From 1 to 2 PSIG |

| Cooling materials | 80 PSIG | From 0.1 PSIG |

| Dust & debris removal | 30 PSIG | From 1 to 2 PSIG |

AIR KNIVES : OUR CURRENT RANGE

An Airtec air knife can offer any one or a combination of air delivery types to dry virtually product size or shape during manufacture. Our bespoke solutions have been integrated in many leading O.E.M suppliers in a wide variety of industries.

We make different types of air knives for our customers, most notably: standard, air cannons, circular and custom. Each project is different, requiring bespoke work to be done to make sure a perfect solution is delivered.

Different Air Knife uses require different pressures to accomplish their tasks. Whilst some can be quite a low pressure, drying or cooling for example, others such as liquid removal need a much higher pressure delivery.

AIR KNIVES AND THE ADVANTAGES OF A BLOWER DRIVEN SYSTEM

Blower driven air knife systems offer a distinct advantage over the compressed air equivalents as much lower pressures are required with a blower driven system to achieve the same result. Upto 90% savings in terms of energy costs are therefore not un-common. The following table illustrates typical pressures required as a comparison.DIFFERENT AIR KNIVES AND WHAT THEY ARE USED FOR

Standard Air Knives

Standard profile airknife for conveyorised applications

Air Cannons

Air Cannons are used when a high mass flow is needed for either distance drying, cleaning or blockage removal.

Circular Air Knives

Circular air knives are mainly used for drying extrusions, wire drying etc

Custom Air Knives

Bespoke designs for applications not suited to the standard airknife profiles are our speciality. Airtec manufactures many component parts for leading OEMs to integrate into new or existing machine builders designs.

Our air knives are bespoke fabricated from food grade 304 or 316 stainless steel, anodised aluminium extrusions are also available.

Our air knives are bespoke fabricated from food grade 304 or 316 stainless steel, anodised aluminium extrusions are also available.

Bespoke air knife options include;

✔ Air Knife (effective air drying up to 300 mm from the product) – bespoke length, fabricated to suit.

✔ Air Cannons (effective air drying up to 2 meters from the product) – 1" to 6" outlet diameter.

✔ Circular Air Knife (effective air drying up to 300 mm from the product) – bespoke diameter, fabricated to suit.

✔ Custom Air Knife – Virtually any size or shape.

Airtec has worked with many great clients, from Aston Martin to Rolls Royce

Airtec has worked with many great clients, from Aston Martin to Rolls Royce

Simple brackets are optionally included with every air knife supplied. Bespoke installation solutions are available, including standalone turn key systems.

Simple brackets are optionally included with every air knife supplied. Bespoke installation solutions are available, including standalone turn key systems.

Commissioning is available if required.

Airtec systems provide the following benefits over compressed air or thermal drying systems;

Airtec systems provide the following benefits over compressed air or thermal drying systems;

✔ Low capital cost

✔ Up to 90% savings on running costs

✔ Fast capital pay back

✔ Reduced noise levels

✔ Improved operator environment

✔ Clean dry air output – our air knife systems do not require expensive filtration

✔ More effective drying capability with Increased productivity

PARTNER WITH US FOR AN END TO END AIR KNIFE SOLUTION

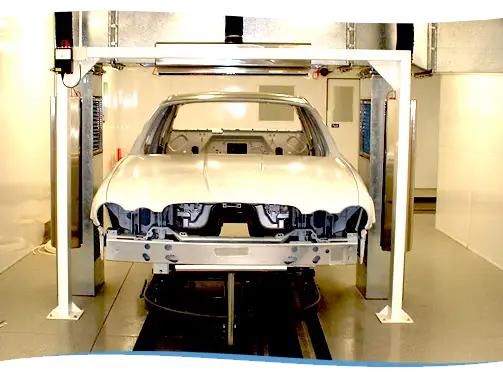

Air Drying System We Created For Aston Martin

We are proud of the working relationships we have with our clients. When you decide to choose Airtec as your air knives provider, you will find that we work closely with you every step of the way through the process until final installation.

Each client is different and each have unique requirements, so no two processes are the same, but here is a general idea of what to expect when we start working together:

- Initial consultation to assess your needs.

- Internal meetings at Airtec to discuss possible solutions.

- Proposal presentation to showcase solutions that we have decided best fit your situation.

- Agreement contract signed and stamped.

- Internal Airtec team creates and completes designs for your bespoke solution.

- Designs are passed to our manufacturing department to be made.

- Our installation team arrives at your site and fits your new solution (if required).

- Contract maintenance begins (if required).

Needless to say, we keep in close contact with you at every stage of the process and there may be extra meetings needed to go over some finer details.

DESIGNING YOUR AIR KNIVES

MAKING YOUR AIR KNIVES

Once the designs are approved, they can get to work transforming them from CAD images to your actual real world product.

Air Knives are traditionally made out of either stainless steel or aluminium depending on the air knife systems application. Both rely on a stream of air exiting the outlet slot direct from the blower source. The coanda effect is naturally created as the external air is entrained along the specially designed outlet slots. The resultant additional mass flow, further improves drying (for example) as there is more weight of air directed towards the product.

An air knife system made from Stainless steel are almost exclusively used and specified in the food, bottling and pharmaceutical industries. They have the advantage of being inherently corrosion resistant. An Aluminium air knife has a hard anodized coating which corrodes very quickly, particular in the high moisture production areas typical of many food manufacturing processes. Industrial cleaning agents are known also to compromise the anodized coating. This can cause particles to ‘flake off’ and contaminate the product.

For areas where corrosive agents/products are present, we can also manufacture a 316 grade stainless steel air knife. The standard supply is 304 grade stainless steel.

Aluminium air knives are more efficient than the stainless steel. Being manufactured from an extrusion, the frictional losses are lower and therefore you can expect an increase in exit air velocity for a given flow/pressure supply when compared to a stainless steel counterpart.

Airtec can supply both stainless steel and aluminium air knives and we will advise on the most appropriate type for the particular application.

The successful performance of any air knife system is wholly dependant on the correct installation and implementation of both the source blower unit and the angle, distance and positioning of the air knives / nozzles etc.

To maximise output and efficiency, careful consideration must be given to the siting of the blowers, angle of discharge, lengths and diameters of supply air pipe runs, air distribution manifolds (if utilised), angle, position and distance of the air knives /nozzles in relation to the product. This is a crucial but often overlooked stage. If poorly implemented, an air knife system can, at best, underperform or at worst not perform at all to customer expectations.

Our air knife installation team have many years direct experience specifically in this field. This will ensure the optimum performance is achieved from any given system. We can also, of course, be on hand to advise should you wish to carry out a self-install with your own team/contractors

AIR KNIFE ACCESSORIES

A range of Air Knife accessories are available. Including acoustic enclosures, water spray enclosures, bespoke brackets, anti-static bars, hosing, fixed ducting and frequency inverters to complete the installation if required.

SOME OF OUR EXISTING CLIENTS AND THEIR PROJECTS

Hydrus

Airtec air systems in conjunction with Hydrus Hygiene Limited were commissioned to improve a number of existing site facilities.

If you are looking for an air knife solution for your workplace, please do give us a call. We happy to chat about any project or problem that you may have that could benefit from one of our bespoke air knife builds and give you any advice you might need.

Our number is 01457 832 724 – we hope to be working with you soon.